Creating an IoT platform for predictive maintenance for CMC

CMC, Belgium based global expert in compressed air control, performance and monitoring solutions, contacted Datylon to explore how they could make better use of available data.The resulting IoT platform ensures that the worldwide network of air compressors can be maintained proactively and predictively, ultimately delivering higher uptimes.

Understanding the challenge

Off-the-shelf commercial IoT platforms offer affordable solutions with a quick time to market, but they generally only address global common denominator problems. This means they are not useful for the growing amount of organizations with very specific global IoT needs, like CMC.

Designing & delivering the solution

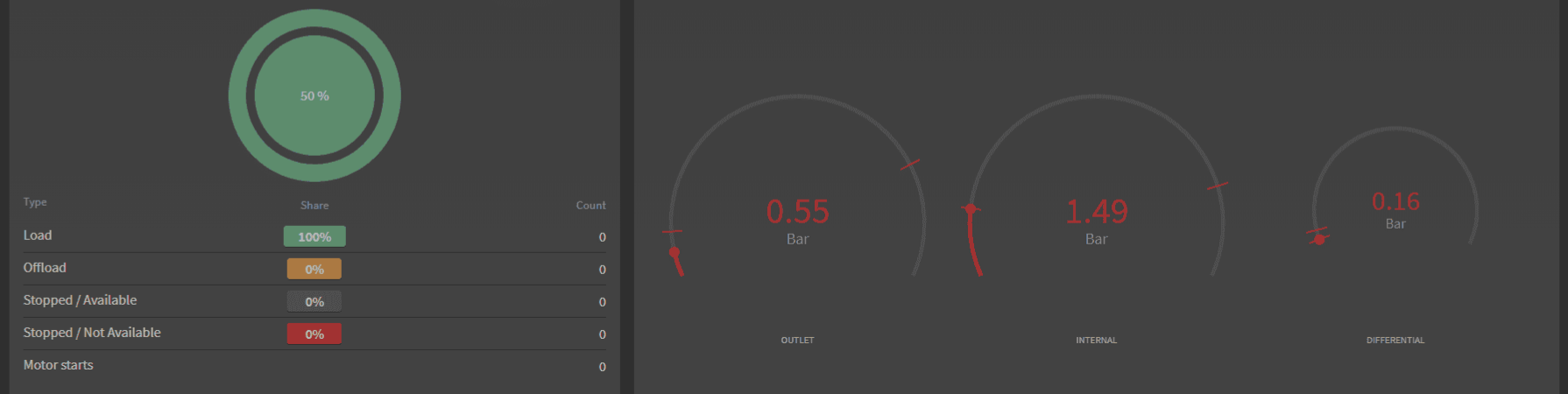

The Datylon projects team created a tailor made, fully scalable, IoT platform, connecting to CMC’s large installed base of air compressor controllers.

A practical UX with the right custom data visualizations and reporting capabilities for each and every stakeholder in the eco-system now ensures that everybody’s job becomes easier and air compressor uptime and efficiency increases.

The delivered business value

The IoT platform ensures that the worldwide network of air compressors can be maintained proactively and predictively, ultimately delivering higher uptimes. Service technicians and distributors have access to faster insights than ever before, resulting in energy savings and less machine downtime.

Need a custom solution too? Get in touch to see how we can tailor a platform to fit your needs.